H.T.H.P. Horizontal Single Vessel Dyeing Plant

Product Details:

- Usage & Applications Industrial

- Pump Type High Efficiency Circulation Pump

- Applicable Material Woven and Knitted Fabrics

- Fabric width Up to 2400 mm

- Power 12 kW

- Manufacturing Year 2024

- No Of Chamber 1

- Click to View more

X

H.T.H.P. Horizontal Single Vessel Dyeing Plant Price And Quantity

- 10 Unit

- Steam/Electric

- Over-pressure and Over-temperature Protection

- Mineral Wool with Stainless Steel Cladding

- 1:5 to 1:8

- Batch

- Provided

- Semi-Automatic

- Stainless Steel (SS 316/304)

- Flanged

- Fast Drain System

- Up to 5 bar

H.T.H.P. Horizontal Single Vessel Dyeing Plant Product Specifications

- Manual

- H.T.H.P. Horizontal Single Vessel Dyeing Plant

- 220 Volt (v)

- Stable Operation

- 2000 kg

- Up to 140C

- Cotton, Polyester, Blends

- 3500 mm x 1800 mm x 2100 mm

- Horizontal Single Vessel

- Variable

- 200 kg

- 800 L

- 2024

- 1

- 12 kW

- Up to 2400 mm

- High Efficiency Circulation Pump

- Industrial

- Woven and Knitted Fabrics

- Steam/Electric

- Over-pressure and Over-temperature Protection

- Mineral Wool with Stainless Steel Cladding

- 1:5 to 1:8

- Batch

- Provided

- Semi-Automatic

- Stainless Steel (SS 316/304)

- Flanged

- Fast Drain System

- Up to 5 bar

H.T.H.P. Horizontal Single Vessel Dyeing Plant Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 2-10 Days

- All India

Product Description

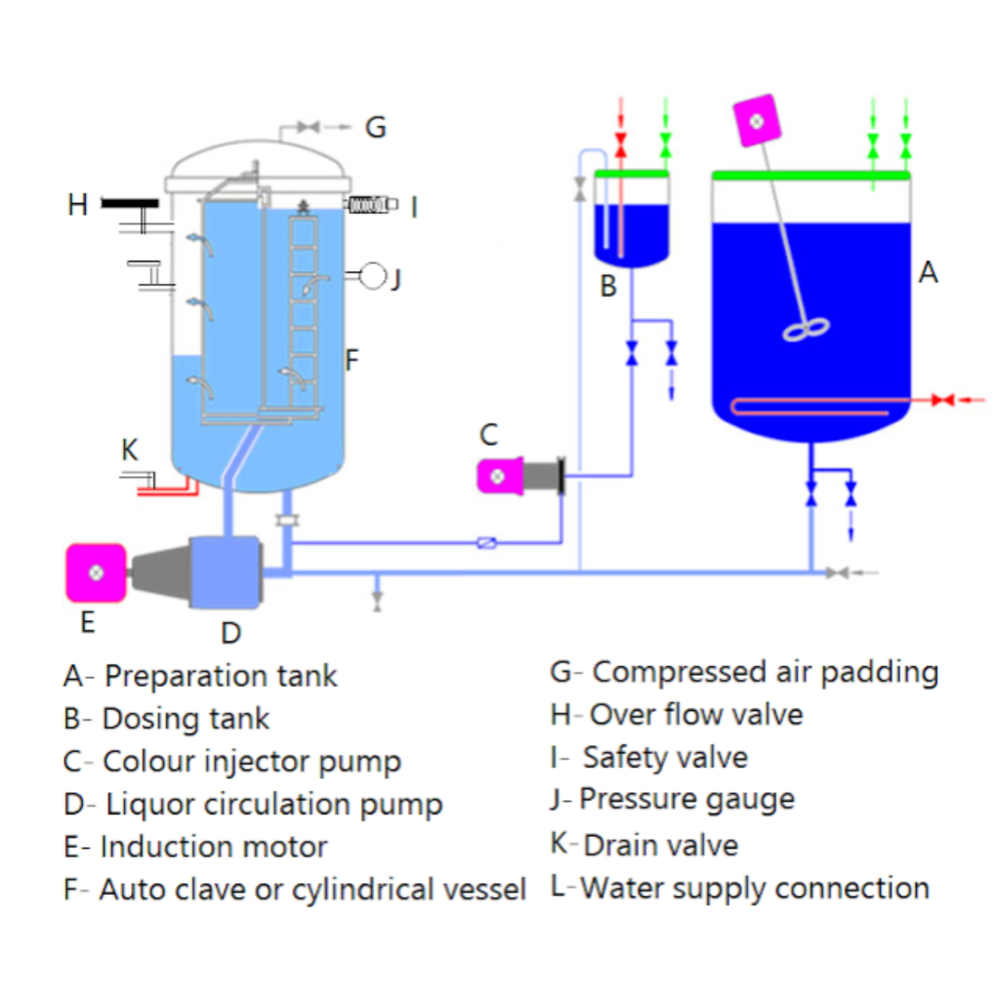

Experience a phenomenal hot deal with this rare, first-class H.T.H.P. Horizontal Single Vessel Dyeing Plant, newly manufactured in 2024. Featuring remarkable engineering with durable SS 316/304 construction and reduced energy consumption, its steam/electric heating and variable speed suit diverse dyeing requirements. Suitable for cotton, polyester, blends, and fabrics up to 2400 mm width, this semi-automatic machine is tailored for industrial excellence. Enjoy remarkable safety, fast draining, and stable operation with exceptional process control. Secure a top-tier investment with this reduced-price opportunity.

Exceptional Industrial Dyeing Performance

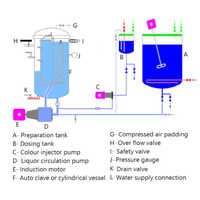

Designed for batch dyeing of woven and knitted fabrics, this dyeing plant provides stable and reliable performance in industrial settings. With competitive advantages such as advanced safety features, rapid drainage, and flexible liquor ratios, it is ideal for high-capacity processing. Simply load fabric, set process parameters, and monitor through the viewing glass for efficient dyeing results. The manual control interface ensures precise adjustment, making it user-friendly for textile technicians.

Order Completion and Export Market Value

Our H.T.H.P. Horizontal Single Vessel Dyeing Plant is available at an attractive market rate, adding value to your production line. We offer fast order completion and dependable supply capacity to support your business growth. Payment terms are flexible for seamless transactions. Supplying across major export markets, our network enables consistent deliveries. Ensure your facility gets first-class equipment with exceptional reliability and technical support on every order.

Exceptional Industrial Dyeing Performance

Designed for batch dyeing of woven and knitted fabrics, this dyeing plant provides stable and reliable performance in industrial settings. With competitive advantages such as advanced safety features, rapid drainage, and flexible liquor ratios, it is ideal for high-capacity processing. Simply load fabric, set process parameters, and monitor through the viewing glass for efficient dyeing results. The manual control interface ensures precise adjustment, making it user-friendly for textile technicians.

Order Completion and Export Market Value

Our H.T.H.P. Horizontal Single Vessel Dyeing Plant is available at an attractive market rate, adding value to your production line. We offer fast order completion and dependable supply capacity to support your business growth. Payment terms are flexible for seamless transactions. Supplying across major export markets, our network enables consistent deliveries. Ensure your facility gets first-class equipment with exceptional reliability and technical support on every order.

FAQs of H.T.H.P. Horizontal Single Vessel Dyeing Plant:

Q: How does the H.T.H.P. Horizontal Single Vessel Dyeing Plant enhance the dyeing process for different fabrics?

A: It delivers efficient batch dyeing for cotton, polyester, and blends, optimizing liquor ratios and temperature settings while accommodating fabric widths up to 2400 mm for remarkable color consistency and uniform results.Q: What safety features are incorporated into this dyeing plant?

A: The plant includes over-pressure and over-temperature protection systems, along with a viewing glass for process monitoring, ensuring operational safety throughout the dyeing cycle.Q: When is the best time to order the latest model for your facility?

A: Ordering the 2024 model now is ideal to secure reduced pricing, benefit from advanced technical features, and ensure timely integration into your production setup.Q: Where can this dyeing plant be used most effectively?

A: It is best suited for industrial textile operations requiring reliable batch dyeing of woven and knitted fabrics, especially where fast drainage and stable operation are essential.Q: What is the process for setting up and operating the dyeing machine?

A: Install the machine with proper water inlet/outlet connections, load fabric, set manual controls for speed and temperature, and monitor the process through the viewing glass for optimal dyeing results.Q: How does purchasing this plant benefit your textile business?

A: It boosts productivity with its high efficiency and quick cycle times, reduces operational costs thanks to energy-saving features, and ensures durable performance with high-grade stainless steel construction.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email